Oil Coolers

Oil coolers are tube heat exchangers that are specifically designed for the transfer of heat, or thermal energy, from heated oil by carrying the oil through cooling units in order to cool it, or using the oil to absorb heat. It can be used to cool items 100°C or higher; unlike water, which has a much lower boiling point. Particularly useful for automotive or mechanical applications, oil is an electrical insulator that is used inside of or in direct contact with electrical components. Read More…

Enerquip is your trusted shell and tube heat exchanger partner. Our in-house, thermal design engineers and ASME welders and fabricators can design and build custom engineered solutions for your company’s specific needs. Our experience and expertise have earned us a preferred supplier status with leading companies in the pharmaceutical, food and beverage, cannabis, personal care, chemical,...

Mason Manufacturing is a custom fabricator of shell and tube heat exchangers, ASME pressure vessels, columns, and tanks. Located in Decatur, Illinois, Mason has over 60 years of experience providing customers with custom fabricated vessels that conform to customer specifications, applicable codes, accepted industry standards and that are consistently shipped on time with competitive pricing. ...

At Tech Fab, we specialize in providing comprehensive solutions for heat exchangers, tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the fabrication industry, we have established ourselves as a trusted leader, known for our unwavering commitment to quality, innovation, and customer satisfaction. Our product offerings encompass a wide range...

Since 1983, we have been providing quality heat transfer products for a wide variety of applications. We repair, rebuild or manufacture heat exchangers, tube heat exchangers, shell heat exchangers and double-wall heat exchangers. Electronics, hospitals and housing industries depend on us.

Since 1930 we have been a leader in providing control solutions and process equipment at McRae Engineering. Our product offerings include heat exchangers, agitators, boilers, vacuum pumps, process heaters, dampers, centrifugal blowers, and more. We also provide various repair services for our customers. Our experienced engineers will work with you to ensure all your specifications are met. Our...

At Lone Star Thermal Engineering, we specialize in providing comprehensive solutions for heat exchangers tailored to meet the diverse needs of our valued clientele. With our expertise in the field of thermal engineering, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of...

More Oil Cooler Manufacturers

Common applications for oil coolers include torque converters, hydraulic and transmission oil cooling in addition to engine oil and compressor oil cooling and waste heat recovery. Engines in vehicles involved with industrial towing or other heavy-duty items have engine oil coolers. For engine oils in particular, maintaining a moderate oil temperature is important as oil functions both as a lubricant and a coolant.

If the oils get too hot the horsepower will drop and the oil will begin to break down, damaging the performance of the engine as the oil is no longer able to provide its lubricating properties. This could result in engine seizure or failure. Oil coolers are used in a wide range of industries such as machine tool, automotive, aerospace, construction, industrial, commercial, chemical processing and electronics.

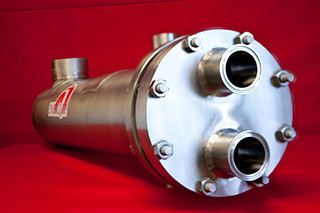

Additional oils that are typically cooled in oil cooler processes include lubricating oils, transformer oils, quenching oils. There are two main types of oil coolers: hydraulic oil coolers and oil air coolers. Hydraulic oil coolers are typically a shell and tube design in which metal wall partitions, known as a tube wall or plate, act as conductors between the two fluids.

Hot oil flows on one side of the barrier and transfers its heat to cooler oils flowing on the other side. Thermal energy only flows from the hotter to the cooler in an attempt to reach equilibrium. The surface area of these partitions affects speed and efficiency: the larger the surface area of a partition, the faster and more efficient the heat transfer.

Oil air coolers are typically a plate, plate and frame or flat plate design in which heat is transferred continuously from heated oil to air without adding energy to the process. The basic concept of an oil air cooler is that the heated oil flows on one side of a thin corrugated metal plate while the comparatively cooler air is on the other; the plate enables the easy transference of heat between the oil to the air. Oil air coolers require less floor space compared to other types of oil cooler equipment and is lighter-weight.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services