Water to Water Heat Exchangers

Water to water heat exchangers transfer heat energy from one liquid to another without bringing the two liquids into direct contact in a similar method as air to air heat exchangers. Typically with a shell and tube or spiral design, water to water heat exchangers work through forcing hot fluids to flow through heat-conducting tubes over which liquid coolants flow. The heat is absorbed by the coolants and thus removed from the water, dropping its core temperature and allowing it to move on in its process. Read More…

Enerquip is your trusted shell and tube heat exchanger partner. Our in-house, thermal design engineers and ASME welders and fabricators can design and build custom engineered solutions for your company’s specific needs. Our experience and expertise have earned us a preferred supplier status with leading companies in the pharmaceutical, food and beverage, cannabis, personal care, chemical,...

Mason Manufacturing is a custom fabricator of shell and tube heat exchangers, ASME pressure vessels, columns, and tanks. Located in Decatur, Illinois, Mason has over 60 years of experience providing customers with custom fabricated vessels that conform to customer specifications, applicable codes, accepted industry standards and that are consistently shipped on time with competitive pricing. ...

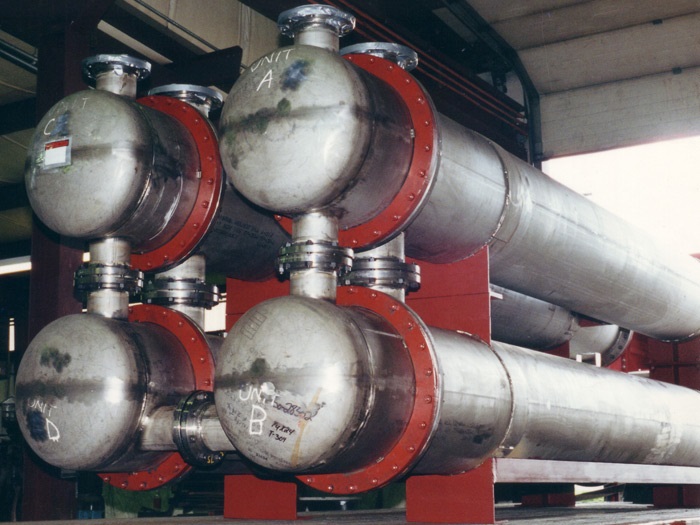

At Tech Fab, we specialize in providing comprehensive solutions for heat exchangers, tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the fabrication industry, we have established ourselves as a trusted leader, known for our unwavering commitment to quality, innovation, and customer satisfaction. Our product offerings encompass a wide range...

Since 1983, we have been providing quality heat transfer products for a wide variety of applications. We repair, rebuild or manufacture heat exchangers, tube heat exchangers, shell heat exchangers and double-wall heat exchangers. Electronics, hospitals and housing industries depend on us.

Since 1930 we have been a leader in providing control solutions and process equipment at McRae Engineering. Our product offerings include heat exchangers, agitators, boilers, vacuum pumps, process heaters, dampers, centrifugal blowers, and more. We also provide various repair services for our customers. Our experienced engineers will work with you to ensure all your specifications are met. Our...

At Lone Star Thermal Engineering, we specialize in providing comprehensive solutions for heat exchangers tailored to meet the diverse needs of our valued clientele. With our expertise in the field of thermal engineering, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of...

More Water to Water Heat Exchanger Manufacturers

Many industrial processes require custom water to water heat exchangers to perform a crucial role in the design, operation and maintenance of heating systems, air conditioning, humidification, water cooling and condensing plants, power generation, refrigeration, chemical processing, offshore oil rigging and industrial engineering systems.

They are also important for process cooling and waste heat recovery in pharmaceutical, food processing, water treatment, textile manufacturing, pulp and paper and steel manufacturing processes. In addition, water to water heat exchangers are especially useful in marine heating applications in which the two main uses include integrating the engine's fresh water cooling system with the hot water heating system and heating domestic water for uses in the galley and shower.

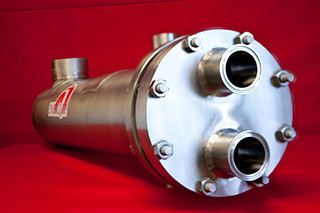

There are different types of heat exchangers that are chosen according to the intended application. However, the most common design for water to water heat exchangers is a shell and tube design. In a shell and tube design there are two separate tanks of water: one tank is reserved for hot water, one tank is for cold. The water from each tank is pumped into a dual chambered reservoir that holds a series of tubes.

The two chambers are separated by a thin layer of highly conductive metal, known as a tube wall, which acts as a conductor between the two fluids. The heated solution flowing on one side of the metal wall transfers its heat through the barrier to a cooler solution flowing on the other side. Thermal energy only flows from the hotter to the cooler in an attempt to reach equilibrium.

The surface area of the tube bundle affect speed and efficiency, and the tubes can be plain, finned or longitudinally finned, and tube diameter, thickness and length should also be taken into consideration. Water is continually pumped through the system to maintain a steady exchange of heat. Water to water heat exchanger manufacturers typically construct exchangers from corrosion-resistant conductive materials such as steel, titanium, copper, bronze, stainless steel, aluminum or cast iron.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services