Heat exchangers are defined as devices that transfer heat from one liquid or gaseous substance to another in order to change the temperature of the substance for another process. Heat exchangers are constructed with thermally conducted tubes or plates. Read More…

Enerquip is your trusted shell and tube heat exchanger partner. Our in-house, thermal design engineers and ASME welders and fabricators can design and build custom engineered solutions for your company’s specific needs. Our experience and expertise have earned us a preferred supplier status with leading companies in the pharmaceutical, food and beverage, cannabis, personal care, chemical,...

Mason Manufacturing is a custom fabricator of shell and tube heat exchangers, ASME pressure vessels, columns, and tanks. Located in Decatur, Illinois, Mason has over 60 years of experience providing customers with custom fabricated vessels that conform to customer specifications, applicable codes, accepted industry standards and that are consistently shipped on time with competitive pricing. ...

For 50 years, Noren Products has delivered innovative thermal management solutions that prevent electronic components from overheating. All of our products are designed and assembled in the USA. Our expert team, including engineering and production, are headquartered in Taylor, Texas.

Since 1953, we have been an industrial heat exchanger and heat transfer systems manufacturer offering shell and tube, marine, plate and frame, brazed plate, welded plate and air cooled heat exchangers and more. To us, service means responsive, knowledgeable support.

Cataract Steel Industries is a renowned leader in the design, manufacturing, and distribution of high-quality heat exchangers and related thermal solutions. Our company has earned a sterling reputation for engineering excellence, innovation, and a steadfast commitment to customer satisfaction. Our core focus revolves around providing a wide array of heat exchangers, including shell and tube,...

Southern Heat Exchanger Corp prides itself on meeting specifications and exceeding expectations in heat transfer equipment. Offering a full range of products and services to satisfy your shell & tube heat exchanger needs, we provide years of experience and a range of materials and capabilities to best serve you. We stand for superior quality in heat exchangers and cooling coils.

More Heat Exchanger Manufacturers

Heat exchangers are heat transferring devices used to move heat from one gaseous or liquid substance to another for the purpose of either heating or cooling a substance for another process. Constructed with thermally conductive plates or tubes, heat exchangers are used to transfer heat from water to water, air to air, water to air or steam to other liquids – such as lubrication oil.

Many industrial processes require heat exchangers to perform a crucial role in the design, operation and maintenance of heating systems, air-conditioning systems, vehicle operation, power generation, refrigeration, chemical processing, offshore oil rigging and engineering systems. They can also be used in the process of waste heat recovery in industrial facilities.

Applications

Heat exchangers are commonly used to transfer heat from air to air, water to water, or air to water to steam or a variety of other liquids. Some of their main applications include: overheating prevention, waste heat recovery, air heating and cooling, and general heat transference.

Overheating Prevention

Heat exchangers are usually depended on by power generation facilities to recycle heat and to prevent processes from overheating.

Waste Heat Recovery

Heat exchangers are also commonly used for waste heat recovery. In this process, excess heat from one process is captured and used in another process that requires heat. Because the waste heat recovery utilizes a pre-existing heat source, the process eliminates the need for fossil fuels or electricity to generate heat, thus saving both energy and money.

Processes that benefit from waste heat recovery include: steel manufacturing, pulp and paper, textile manufacturing, water treatment, food processing, and pharmaceutical.

Air Cooling

In addition to heating different substances, heat exchangers can also be used to cool air for air conditioning and refrigeration.

General Heat Transference

In addition, heat exchangers can be used in energy, chemical, and mechanical systems for processes that require the transferring of heat to some degree. For example, the radiator of a car is responsible for transferring heat to the air from the vehicle’s engine.

Industries that use heat exchangers for their processes and equipment include: automotive, electronic, chemical, energy, petrochemical, mechanics, semiconductor, marine, and aerospace.

There are numerous processes that require heat exchangers. Heat exchangers play a vital role in the operations and design of numerous machines, such as: air-conditioning systems, heating systems, power generators, vehicles, refrigerators, oil rigs, and various engineering and chemical processing systems. Heat exchangers are used for other commercial purposes including: hot tub and swimming pool heaters, hot water radiators, and home radiators.

History

The concept of heat transfer, or heat exchange, has been around more or less since man discovered fire. The earliest heat exchangers were rocks. After being heated in the fire, residents would place them inside their huts, where they would radiate that heat. Some time later, the Romans invented central heating, which is known today as the hypocaust. The hypocaust system worked by transferring hot air from the floor to the room. The hot air came from the fire in a furnace maintained by slaves, and it escaped the floor via a created space in concrete or tiles.

Residents of the Korean Peninsula later adopted a similar system, which they called Ondol heating. Ondol heating worked by directing smoke and hot air generated by wood fires through pipes underneath the floors.

Heat exchanger systems began to diversify in use during the Industrial Revolution. For example, in 1777, Frenchman Jean Simon Nonnemain, sometimes called the father of hot water central heating, developed a water heating system that assisted in chicken egg incubation. In 1817, another Frenchman, Marquis de Chabannes, invented a heat exchanger for use in a greenhouse. It created enough heat to help grow grapes.

A few years later, in 1829 to be exact, the Price brothers of Bristol received a patent in England for home heating. It relied on hot water and steam heating. Following the introduction of their system, engineers around the world met great success as they worked hard at improving and expanding steam heat exchangers and hot systems.

In 1855, a Russian man named Franz San Galli designed an early version of a hot water radiator, which he called a hot box. His invention was wildly popular with the aristocratic and wealthy members of the St. Petersburg society, who heavily commissioned his work for their homes and palaces.

Meanwhile, in the United States, heat exchangers had been gaining popularity for several years. A number of American inventors were patenting their steam radiators including Nason, Perkins, and Briggs in 1862. Nelson H. Bundy patented his cast iron radiator in 1872. The latter model proved most popular and was used as a model for other inventors all over the world.

By the turn of the 20th century, heat exchangers, particularly radiators, were popular and widely produced. From that point on, manufacturers focused on creating heat exchangers that were safer, stronger and more efficient. As heat exchanger technology has become more proficient and material choices have widened, they have done just that. Today, heat exchanger developers gather more of their thermal energy from renewable, solar power.

How It Works

Plate and tubular heat exchangers vary in terms of structure, but both utilize the same concepts of thermodynamics. The conductive metal plates or tube walls act as partitions and conductors between the two gases or fluids and keep the two substances separate at the same time.

These plates and walls are commonly made from stainless steel, due to the metal’s high durability and its ability to act as a conductor while enduring high pressures and extreme temperatures. On one side of the barrier, a heated substance transfers its heat to the cooler solution on the other side, which temporarily creates thermal stress inside the wall or tube.

In order to eliminate the thermal stress and achieve equilibrium, the thermal energy gravitates toward the cooler solution. The efficiency and speed of the process depends greatly on the size of the surface area of the partition. The larger the partition’s surface area, the quicker the heat will transfer.

Types

There are countless varieties of heat exchangers. To make things easier, we can break them down into groups of plate heat exchangers and tubular heat exchangers. They are both indirect heat exchangers that utilize a metal that separates the fluid or steam from the heating unit. The heat must pass through the metal wall instead of making direct contact.

Plate Heat Exchangers

Plate Heat Exchangers use plates to separate fluids. Generally, they feature a high surface area-to-volume ratio and can process more than two types of fluid and steam at once. Most often, they’re used in cryogenic applications and food processing applications.

Plate heat exchangers come in two basic configurations—flat plate heat exchangers or plate and frame heat exchangers. Countless other exchangers fall under this category.

Flat plate heat exchangers transfer heat through plates that are flat and corrugated.

Plate and frame heat exchangers are large plate heat exchangers used with HVAC applications. They feature rectangular plates held together by membranes and are sealed by gaskets. Sometimes, they’re welded together in order to safeguard against leakage. The rectangular plates feature holes through which fluids can pass.

Plate-fin heat exchangers are so named because they’re made up of parallel jointed plates, interlocked using fins. Plate-fin exchangers offer the advantage of versatility. Due to their arrangement, they permit the exchange of around 12 fluid flows within one exchanger. Also, they allow for either cross-flow or parallel flow in between adjacent plates. Able to operate within close temperature limits, plate-fin exchangers are popular in gas liquefaction.

Spiral plate heat exchangers feature two flat, parallel plates that have been wound to form a coil, and terminals that are either gasket-sealed or welded. Spiral heat exchangers are best used with fluids that carry fibers or particles, and heavy viscous fluids that may cause fouling.

Air to air heat exchangers maintain fresh air by removing stale indoor air and replacing it with fresh outdoor air.

Water to air heat exchangers, as their name suggests, are designed to pass heat energy from water to the air.

Tubular Heat Exchangers

Tubular Heat Exchangers feature tubular elements that allow them to cater to a wide range of temperatures and pressure levels.

Some of the most common tubular heat exchanger configurations include: shell and tube heat exchangers, finned tube heat exchangers, air-cooled heat exchangers, oil coolers, marine exchangers and water-to-water heat exchangers.

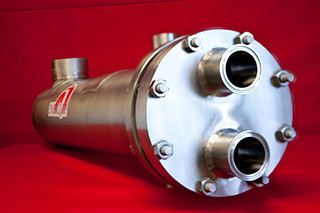

Shell and tube heat exchangers (shell-and-tube heat exchangers) consist of several tubes mounted inside a cylindrical metal shell. The shell allows for the exchange of heat from the fluid inside or outside the tube(s). Shell and tube heat exchangers have four main components: the front end, the rear end, the tube bundle, and the shell. The front end is the area through which the fluid enters, while the rear end is the area through which it exits. The tube bundle consists of the tubes, tube sheets, and tie rods that hold them all together. Finally, the shell holds the tube bundle.

Finned tube heat exchangers are simply heat exchangers that feature finned tubes. Fins allow for higher efficiency.

Air-cooled heat exchangers cool air as it is exchanged through tube bundles. They do so using a fan system placed above the bundles, where it creates a draught, and finned tubes that suck in the air and increase surface area. They work best where you can’t use cooling water or fluid efficiently.

Oil coolers transfer thermal energy (heat) through oil that needs cooling. They do so by carrying the heated oil through cooling units.

Marine heat exchangers are those heat exchangers used on ships, boats and other marine vehicles. Typically, they work using a water-to-water configuration.

Water to water heat exchangers indirectly heat one liquid using the heat energy from another liquid.

Benefits

Heat exchangers compete against various methods of heat transfer and temperature control in numerous applications. One common competitor is direct-fired systems, such as boilers and furnaces, which generate heat by burning fuel. While these systems are effective in some scenarios, they can be less efficient and produce harmful emissions. Another competitor is electric resistance heating, which converts electrical energy into heat. However, it can be costly and less energy-efficient compared to heat exchangers.

Heat exchangers offer several significant benefits over these alternatives. One key advantage is lower maintenance costs. Heat exchangers operate in a closed-loop system, separating the hot and cold fluids, which reduces the risk of corrosion and wear. In contrast, direct-fired systems often require frequent maintenance and cleaning, leading to higher operating expenses.

Improved performance is another benefit of heat exchangers. By efficiently transferring heat between two fluids without mixing them, heat exchangers ensure precise temperature control. This results in consistent and optimal process performance, while direct-fired systems can have temperature fluctuations that impact product quality and efficiency.

Time and energy savings are crucial advantages provided by heat exchangers. Their design facilitates rapid heat transfer, reducing the time required to achieve desired temperatures. Moreover, they promote energy conservation by reusing waste heat or extracting heat from secondary sources. This results in lower energy consumption compared to direct-fired systems, where energy is primarily lost through exhaust gases.

Additionally, heat exchangers contribute to improved safety and reduced environmental impact. Compared to direct-fired systems, they have a lower risk of accidents and lower greenhouse gas emissions, making them more environmentally friendly and compliant with regulations.

An often overlooked benefit of heat exchangers is their ability to enable heat recovery and cogeneration. They allow businesses to harness and repurpose excess heat for other processes, enhancing overall efficiency and reducing waste. In contrast, direct-fired systems typically release excess heat into the atmosphere, resulting in missed opportunities for energy reuse.

In summary, heat exchangers stand out as a superior choice due to their lower maintenance costs, improved performance, time and energy savings, enhanced safety, reduced environmental impact, and the potential for heat recovery and cogeneration. These advantages make heat exchangers an efficient and eco-friendly solution for various industrial, commercial, and residential applications, outperforming their competitors in the field of heat transfer and temperature control.

Design and Customization

When designing commercial or industrial heat exchangers, manufacturers consider application specifics such as: minimum and maximum heat, type of fluid flow, rate of fluid exchange, rate of flow, possible fluid flow contaminants, required flow and heat exchange efficiency levels, and standard requirements. These considerations help them decide factors such as tube thickness, tube material, tube length, tube pitch, tube layout, fluid flow design and tube corrugation.

Depending on the overall function and location, manufacturers may design heat exchangers using any one of a variety of configurations. Generally, they build heat exchangers with a flat plate design or a shell and tube design. Air, liquid, or steam flow through a network of heat conducting tubes or cavities lined with heat conducting plates.

Heat exchanger manufacturers construct their products from materials that are corrosion resistant and durable, such as cast iron, aluminum, steel, stainless steel, bronze, copper, and titanium.

Manufacturers customize their designs in a number of ways. For example, if the application calls for it, manufacturers will bend tubes into a “u” shape, making what is called a u-tube heat exchanger.

Things to Consider

Caring for Your Heat Exchangers

Corrosion is the most prominent issue in heat exchangers and is difficult to avoid due to the constant high levels of humidity and flow of liquids. Fortunately, you can minimize corrosion-related system running problems by using walling and tubing that is resistant to leaching, cracking, pitting, and corrosion.

There are also liquids that can cause residue to build up over time. The residue can be cleaned, and the cleaning process can be done without too much delay.

How to Choose the Right Manufacturer

For high quality heat exchangers, you need to work with a high-quality heat exchanger manufacturer. We’ve compiled profiles of heat exchanger suppliers we trust. You will find those profiles nestled in between the information paragraphs throughout this page. Before you scroll up to look at them, we recommend you create a list of specifications. That way, you can consult them as needed. Make sure to specify things like fluid type, fluid flow type, your available space, your budget, your timeline, any standard requirements and your custom requests. Once you’ve completed your list, start browsing. Select three or four companies and reach out to them. Discuss your application at length, taking notes as you go. After consulting with each of them, look over your notes to determine which manufacturer is right for you. Once you’ve figured that out, give them a call and get started.

Check out our Heat Exchangers website

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services